Ball joints are one of the most critical yet overlooked components in a vehicle’s suspension system. They act as the pivot points between the control arms and the steering knuckles, allowing smooth movement and stability during driving. In simpler terms, a ball joint enables the wheels to move up and down with the suspension while also allowing them to turn left and right. Understanding how a ball joint works, its common issues, and the right maintenance practices is essential not only for vehicle performance but also for road safety. Most drivers become aware of their ball joints only when steering feels loose or when they hear a clunking sound over bumps. This article explores in-depth what a ball joint does, how to identify signs of wear, and how replacement can restore driving precision.

Understanding the Function of a Ball Joint

A ball joint functions similarly to the human shoulder joint—it allows rotational movement in multiple directions while maintaining structural support. It connects the vehicle’s suspension control arms to the steering knuckles, providing both stability and flexibility. In a standard double-wishbone suspension system, there are usually two ball joints per wheel: one upper and one lower. The lower ball joint carries most of the vehicle’s weight, while the upper joint helps with alignment and steering geometry. When a car moves, these joints allow the wheels to follow the contours of the road without compromising handling. “A well-maintained ball joint ensures that the steering remains predictable and the tires maintain consistent contact with the road,” says automotive engineer Paul Henley.

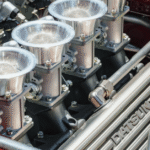

Types of Ball Joints in Modern Vehicles

Ball joints come in several designs depending on vehicle type and suspension architecture. The two main categories are load-carrying and follower ball joints. Load-carrying joints bear the weight of the vehicle and absorb most of the vertical forces, whereas follower joints primarily handle steering input. They can be either sealed (maintenance-free) or greaseable (serviceable). Sealed joints are common in modern cars and trucks, as they require less maintenance. However, greaseable types are still preferred in heavy-duty or off-road vehicles, as they can be periodically lubricated to extend lifespan. Manufacturers also use variations like press-in, bolt-on, or screw-in designs, each suited to specific vehicle models.

Table 1: Common Types of Ball Joints and Their Applications

| Type of Ball Joint | Maintenance Type | Typical Vehicle Use | Key Advantage |

|---|---|---|---|

| Load-Carrying | Greaseable | Trucks, SUVs | Handles heavy weight effectively |

| Follower | Sealed | Passenger cars | Smooth steering control |

| Press-In | Non-Serviceable | Sedans | Compact and durable design |

| Bolt-On | Serviceable | Off-road vehicles | Easy to replace |

| Screw-In | Greaseable | Classic and modified vehicles | Adjustable and repair-friendly |

How Ball Joints Affect Vehicle Performance

The health of your ball joints directly influences your vehicle’s alignment, tire wear, and overall driving comfort. When these joints wear out, the wheels can tilt outward or inward, leading to uneven tire wear and unstable handling. This often results in the car pulling to one side during acceleration or braking. Additionally, worn joints can cause excessive vibration or “shimmy” in the steering wheel, especially at high speeds. Over time, a neglected ball joint can even break apart, causing complete loss of control. “The connection between safety and suspension integrity cannot be overstated,” notes automotive technician Clara Reynolds. “A compromised ball joint isn’t just a repair issue—it’s a potential safety hazard.”

Symptoms of a Worn Ball Joint

Detecting a failing ball joint early can prevent expensive repairs and potential accidents. Common signs include clunking noises when going over bumps, uneven tire wear, or excessive steering play. You may also notice a knocking sound from the front suspension when turning the wheel. Another telltale symptom is vehicle drifting or pulling during straight-line driving. In severe cases, one side of the car may sit lower due to a collapsed joint. Mechanics often check ball joints using a pry bar or by lifting the wheel to test for movement. Any noticeable looseness or clicking indicates wear and the need for immediate replacement.

The Replacement Process and Costs

Replacing a ball joint depends on the type of vehicle and the joint’s installation design. Press-in joints typically require a hydraulic press for removal, while bolt-on or screw-in types are simpler to replace. The average labor cost can range from $150 to $400 per joint, depending on the make and model. For vehicles with integrated control arm assemblies, replacement may cost more since the entire component must be changed. Most mechanics recommend replacing both sides simultaneously to ensure even suspension behavior. Additionally, a post-replacement wheel alignment is mandatory to restore proper geometry and handling precision.

Table 2: Estimated Ball Joint Replacement Costs by Vehicle Type

| Vehicle Type | Average Parts Cost | Labor Cost Range | Recommended Replacement Interval |

|---|---|---|---|

| Compact Car | $50 – $100 | $150 – $250 | Every 80,000–100,000 miles |

| SUV/Truck | $100 – $200 | $200 – $400 | Every 60,000–80,000 miles |

| Sports Car | $80 – $150 | $180 – $300 | Every 70,000–90,000 miles |

| Heavy-Duty Pickup | $150 – $250 | $300 – $450 | Every 50,000–70,000 miles |

Maintenance Tips for Longevity

Proper maintenance of ball joints can significantly extend their lifespan. Regularly inspecting suspension components during tire rotations or oil changes helps identify early wear. For greaseable joints, applying fresh lubricant every 5,000 miles can reduce friction and prevent corrosion. Avoid overloading your vehicle or driving aggressively over potholes, as these habits strain the suspension system. It is also advisable to replace damaged dust boots promptly since they protect the joint from dirt and moisture. Drivers should remember that a minor squeak or vibration today could turn into a costly repair tomorrow if ignored. Preventive care remains the most affordable path to vehicle reliability.

Ball Joints in Modern Suspension Design

Automotive engineers have evolved the ball joint’s design over decades to meet the demands of modern driving. In contemporary vehicles, ball joints are crafted from high-tensile steel alloys with polymer-coated bearings for friction reduction. Many premium models use advanced spherical bearings that offer near-frictionless motion and longer service life. Electric and autonomous vehicles incorporate electronic monitoring systems that alert drivers to joint wear through dashboard indicators. The integration of lightweight materials like carbon composites in suspension arms has also improved performance efficiency while maintaining durability. These innovations highlight how a simple mechanical part continues to evolve with technological advancements in mobility.

Safety and Handling Considerations

A vehicle’s ability to corner, absorb shocks, and maintain road contact depends heavily on its ball joints. They serve as the mechanical heart of the suspension system, translating steering wheel input into smooth directional movement. When functioning correctly, ball joints contribute to precise alignment and optimal braking distance. However, a worn or broken joint can severely impact safety by causing erratic wheel movement or sudden tire collapse. Safety experts recommend inspecting ball joints during every major service or before long-distance trips. As one industry quote wisely puts it, “Suspension parts don’t fail overnight—they whisper before they scream.” Recognizing these whispers can prevent serious incidents on the road.

Comparing OEM vs Aftermarket Ball Joints

When replacing a ball joint, the choice between OEM (Original Equipment Manufacturer) and aftermarket parts matters significantly. OEM joints are designed to match factory specifications, offering predictable performance and fit. Aftermarket joints, however, may come with enhanced materials or designs, such as improved grease fittings or reinforced housings. While OEM options tend to be more expensive, they ensure consistent quality and compatibility. Performance enthusiasts often prefer aftermarket variants for their customizable features and higher load tolerance. The key lies in balancing cost, longevity, and intended vehicle use. Consulting a trusted mechanic can help determine which option best suits your driving needs.

Importance of Alignment After Ball Joint Replacement

Wheel alignment is an essential step after replacing any suspension component, especially ball joints. Since these joints directly influence wheel angles, any alteration in their position can misalign the tires. Poor alignment leads to uneven wear, reduced fuel efficiency, and unpredictable steering. Technicians typically perform a four-wheel alignment to recalibrate the vehicle’s camber, caster, and toe angles. Neglecting this step can offset the benefit of the new parts, reducing handling precision. Alignment is not merely a finishing touch—it’s a necessary calibration to ensure every replaced component performs as intended.

Common Myths About Ball Joints

Many misconceptions surround ball joint maintenance. One common myth is that sealed ball joints never need attention. In reality, even sealed joints wear out over time and must be inspected regularly. Another misconception is that squeaky suspension always means bad shocks; in truth, it could be a dry or failing joint. Drivers also believe that ball joint replacement is needed only when noise becomes severe, but early intervention prevents expensive damage to control arms and tires. Understanding these myths helps drivers take a more proactive role in maintaining their vehicle’s suspension system effectively.

Environmental Factors That Affect Ball Joint Durability

Environmental conditions play a substantial role in determining ball joint lifespan. Vehicles operated in areas with extreme temperatures, heavy rain, or salted winter roads experience faster wear. Moisture and road salt corrode metal components, while heat accelerates grease breakdown. Off-road driving also subjects joints to mud, debris, and constant vibrations. To counteract these challenges, modern ball joints often include protective rubber boots and synthetic grease formulations designed to resist moisture and oxidation. In challenging climates, scheduling more frequent inspections and cleaning undercarriage components can make a noticeable difference in longevity.

Technological Advances in Ball Joint Manufacturing

The manufacturing of ball joints has evolved from basic metal forging to precision-engineered systems. Today’s joints are designed using computer-aided simulations to ensure optimal load distribution and motion dynamics. Advanced surface treatments like zinc plating and Teflon coating have improved resistance against corrosion and friction. Furthermore, robotic assembly processes guarantee consistent quality across production batches. Manufacturers now use embedded sensors to detect joint wear and send diagnostic data to onboard vehicle systems. Such innovations not only enhance durability but also transform the maintenance process from reactive to predictive.

Ball Joint Failure and Accident Risks

A failed ball joint can cause the suspension to collapse, leading to complete loss of steering control. This can be catastrophic if it occurs at high speeds. The lower ball joint is particularly critical since it supports the vehicle’s weight. When it fails, the affected wheel can fold inward, causing the car to drop suddenly. In such cases, damage often extends to tires, axles, and even the brake system. Drivers who experience loud bangs or sudden drops should not attempt to move the vehicle and should call for professional assistance immediately. Preventive inspection remains the most reliable safeguard against these dangerous outcomes.

Choosing Quality Replacement Parts

Not all ball joints are created equal. The quality of materials and manufacturing precision determines how long they last. Premium brands often feature hardened steel housings, precision ball bearings, and dust-resistant seals. Cheaper alternatives might save money initially but can wear out quickly or fail under heavy loads. When shopping for replacements, look for certifications such as ISO/TS 16949 or OEM-equivalent ratings. “It’s one of those parts where quality directly translates into safety,” remarks automotive restorer Mike Delgado. Investing in reputable components is an investment in the reliability and stability of your entire vehicle.

Ball Joints and Vehicle Comfort

The smoothness of your ride depends significantly on how effectively the suspension components absorb road irregularities. Healthy ball joints allow fluid motion between the wheel and suspension system, preventing harsh vibrations from reaching the cabin. When joints start binding or loosening, passengers may feel increased noise, vibration, and harshness (NVH). This affects not only comfort but also driver fatigue over long distances. Thus, even in non-performance vehicles, maintaining these joints ensures a quiet, stable, and refined driving experience. Automakers have recognized this, designing newer models with noise-dampening joint housings for improved comfort.

Future of Ball Joint Technology

The future of ball joint design lies in integrating smart technologies that monitor performance in real time. Engineers are experimenting with self-lubricating materials and miniature sensors that track friction levels and wear. Some concept vehicles already use adaptive suspension systems where electronic actuators adjust joint stiffness based on driving conditions. These innovations promise longer life spans and enhanced driver feedback. As automotive technology continues evolving toward automation and electrification, the humble ball joint will remain indispensable—quietly supporting every curve, turn, and mile traveled.

Conclusion

Ball joints might be small, but their role in ensuring vehicle safety and performance is enormous. They form the critical connection that enables steering precision, suspension flexibility, and stable driving. Understanding how they work, recognizing symptoms of wear, and maintaining them properly can save both money and lives. In an era of advanced automotive technology, even the simplest mechanical components continue to evolve. As the saying goes, “Every great machine depends on its smallest part.” Keeping your ball joints healthy ensures your vehicle remains dependable, comfortable, and safe for every journey ahead.

FAQs

1. How long do ball joints typically last?

Most ball joints last between 80,000 and 100,000 miles under normal driving conditions. However, harsh terrain or poor maintenance can shorten this lifespan. Regular inspections help detect wear before it becomes critical.

2. Can I drive with a bad ball joint?

Driving with a failing ball joint is extremely risky. It can lead to sudden suspension collapse or loss of control. Always replace worn joints immediately.

3. How can I tell if my ball joint needs replacement?

Look for clunking noises, uneven tire wear, or excessive steering looseness. A mechanic can confirm with a physical inspection.

4. Are greaseable ball joints better than sealed ones?

Greaseable joints last longer if maintained properly, but sealed joints require no servicing. The choice depends on driving conditions and vehicle type.

5. Should both ball joints be replaced at the same time?

Yes, replacing both ensures even suspension behavior and alignment accuracy. It prevents uneven wear and provides balanced handling.