In a world driven by innovation, precision, and constant evolution, One Technicals stands out as both a concept and a methodology designed to unify complex processes into a single, streamlined approach. At its core, One Technicals represents the consolidation of knowledge, tools, and systems into one coherent operational framework, making it easier for organizations and individuals to achieve high-efficiency outcomes. Whether in engineering, digital product development, industrial manufacturing, or even creative design, the One Technical principle ensures every action, every decision, and every resource is aligned toward a single technical objective.

The search intent behind “One Technicals” often stems from individuals seeking a clear explanation of what it means, how it is applied in practical terms, and why it is increasingly relevant in today’s competitive industries. In this guide, we will break down its conceptual framework, examine its real-world applications, and highlight its measurable benefits. We will also explore how it can serve as a bridge between technicals expertise and strategic business growth. In doing so, this article will provide readers with a comprehensive view that is not only informational but also immediately applicable to their own projects or organizations. As the name implies, One Technical is about singular focus—removing unnecessary complexity and ensuring technical efforts align seamlessly with desired results.

Understanding the Core of One Technical

One Technicals can be viewed as both a philosophy and a practical framework. It operates on the premise that when all technicals components, from planning to execution, operate under one unified approach, inefficiencies naturally decline. The term often applies to scenarios where multiple teams, tools, and systems are integrated into a single operational ecosystem. This might include engineering pipelines that merge design, prototyping, and testing in one platform or business models where technology, strategy, and communication work hand in hand. By reducing fragmented workflows, One Technicals empowers organizations to make faster decisions and adapt more effectively to change.

The Origins of the One Technical Approach

While the phrase “One Technicals” feels modern, its roots can be traced back to early industrial management systems. Historically, industries struggled with siloed departments, where engineering, production, and quality assurance worked in isolation. The rise of integrated manufacturing in the mid-20th century introduced the notion of “one process for all,” which later evolved into a more technically refined strategy. In the digital age, the approach shifted toward merging digital tools, software engineering, and automation under one technicals authority. The concept’s endurance shows that regardless of industry shifts, the principle of unification remains timeless.

Why One Technical Matters Today

In today’s market, where speed and adaptability determine survival, One Technical ensures that every technicals decision contributes to the same overarching goal. This is particularly critical in high-tech sectors like aerospace, AI development, and energy systems, where misaligned processes can result in costly delays. Businesses that adopt One Technical are more likely to reduce redundancy, improve quality control, and enhance cross-functional collaboration. Furthermore, this approach creates a consistent standard across projects, making it easier to scale innovations without sacrificing reliability.

Key Components of One Technical

For One Technical to work effectively, several foundational components must be in place:

- Centralized Knowledge Base – A shared repository of technicals documentation, guidelines, and updates.

- Integrated Tools – Platforms and software that enable seamless data sharing and process tracking.

- Unified Communication Channels – Ensuring engineers, managers, and stakeholders work from the same set of information.

- Cross-Functional Skill Alignment – Encouraging teams to understand multiple aspects of a project beyond their immediate role.

These elements collectively create the ecosystem that allows One Technicals to thrive in both small teams and large organizations.

Table 1: Core Principles vs. Benefits of One Technical

| Core Principle | Description | Key Benefit |

|---|---|---|

| Centralization | Single source of truth for all technical data | Eliminates conflicting information |

| Integration | Unified tools and platforms | Faster and more accurate project execution |

| Communication Alignment | Clear, consistent communication methods | Fewer misunderstandings and rework |

| Skill Interconnection | Teams understand adjacent technical domains | Greater adaptability in problem-solving |

How One Technical Differs from Traditional Methods

Traditional methods often focus on departmental expertise, where each team works within its own specialized scope. While specialization has advantages, it also creates bottlenecks when teams must coordinate across different systems and standards. One Technicals takes a holistic view, promoting shared goals and removing barriers between specializations. This creates a more adaptive, agile environment where changes can be implemented without overhauling entire systems.

The Role of Technology in One Technical

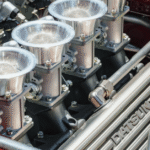

Modern technology acts as both the enabler and the amplifier of the One Technical approach. Cloud computing, real-time collaboration tools, and AI-driven analytics provide the infrastructure for integrated technical operations. For instance, in product design, AI can analyze manufacturing constraints while designers are still working on prototypes, enabling quicker adjustments. In software development, integrated DevOps pipelines ensure that code deployment, testing, and monitoring all happen in a coordinated, automated fashion.

Implementing One Technical in an Organization

To implement One Technicals effectively, an organization should start by assessing its current workflow fragmentation. From there, leadership can establish a unified technical strategy that outlines shared objectives, tools, and communication methods. Training is essential to ensure that all team members understand the broader framework and can operate within it. Finally, regular performance reviews should measure how well the approach is reducing inefficiencies and increasing output quality.

Table 2: Implementation Roadmap for One Technical

| Phase | Action Step | Expected Outcome |

|---|---|---|

| Assessment | Identify current workflow silos | Clear understanding of integration needs |

| Strategy | Define unified technical objectives | Organization-wide alignment on priorities |

| Training | Educate teams on One Technical principles | Smooth transition to integrated operations |

| Optimization | Monitor and adjust processes | Continuous improvement in efficiency |

Challenges and Solutions in Adopting One Technical

Transitioning to One Technical can present challenges such as resistance to change, the complexity of integrating old systems, and the initial learning curve for teams. Solutions often include phased implementation, incentives for cross-departmental collaboration, and adopting flexible software platforms that can bridge legacy tools with new systems. Leadership commitment is critical—without clear direction from the top, the unification effort can lose momentum.

One Technical in Action: Industry Examples

In the automotive sector, One Technicals might involve uniting design, simulation, and production in a shared digital twin environment. In the healthcare industry, it could mean integrating patient data systems, diagnostics, and treatment planning into one synchronized platform. Even in creative industries like filmmaking, One Technicals principles help align production scheduling, special effects, and editing within a single software ecosystem, reducing turnaround times dramatically.

Long-Term Impact of One Technical

The long-term benefits of adopting One Technical include higher operational agility, stronger innovation pipelines, and improved cost control. Over time, organizations may find that this unified approach fosters a culture of collaboration where technical and strategic objectives naturally align. In a fast-changing market, the ability to pivot quickly while maintaining technical precision can be the difference between thriving and falling behind.

Conclusion

One Technical’s more than a buzzword—it is a strategic necessity in today’s interconnected industries. By consolidating resources, aligning teams, and centralizing processes, it reduces inefficiencies while boosting adaptability. Whether in engineering, healthcare, technology, or creative fields, the principles of One Technicals can transform how organizations operate. As industries continue to evolve, those that adopt this approach will be better positioned to innovate, scale, and deliver consistent quality. As one industry expert put it, “Integration isn’t the future—it’s the present, and One Technical is how we master it.” Another leader noted, “When everyone pulls in the same technical direction, progress becomes inevitable.”

FAQs

1. What does “One Technical” mean in practical terms?

One Technicals refers to a unified approach where all technical processes, tools, and teams operate under a single coordinated framework. It reduces workflow fragmentation, improves communication, and ensures that every action contributes toward a shared technical goal.

2. Which industries can benefit most from One Technical?

While applicable across sectors, industries like manufacturing, software development, aerospace, healthcare, and creative production gain significant advantages from One Technicals. These fields often face complex, multi-departmental challenges that unified technical strategies can resolve.

3. How is One Technical different from project management?

Project management focuses on timelines, budgets, and deliverables, while One Technical specifically addresses the integration of technicals processes, tools, and expertise. It complements project management by ensuring all technical efforts align with the broader objectives.

4. What challenges might an organization face in adopting One Technical?

Common challenges include resistance to change, difficulty integrating old systems, and the learning curve for new tools. These can be addressed with phased implementation, strong leadership support, and comprehensive training.

5. Is One Technical suitable for small businesses or only large corporations?

One Technical’s adaptable to any scale. Small businesses can use it to maximize efficiency with limited resources, while large corporations can leverage it to coordinate complex, multi-departmental projects.