Lang Tools, a respected name in the world of professional-grade hand tools, stands as a testament to the balance of durability, precision, and innovation in mechanical craftsmanship. For decades, the brand has been synonymous with reliability, producing tools that cater to automotive technicians, industrial mechanics, and even demanding home users. At its core, Lang Tools focuses on delivering instruments that simplify complex tasks—ranging from brake caliper presses to specialty wrenches—while ensuring they can withstand rigorous daily use. Anyone searching for Lang Tools likely seeks clarity on the company’s product range, manufacturing quality, and why it maintains an enduring presence in competitive markets. This guide provides an in-depth look at its evolution, key products, design philosophy, and influence on the global tool industry. By the end, you’ll understand not just what Lang Tools makes, but how its approach to engineering has secured its position as a trusted choice among professionals.

The Origins and Heritage of Lang Tools

Lang Tools traces its heritage to a time when American manufacturing was defined by skilled craftsmanship and robust materials. Founded in the mid-20th century, the company began by producing specialized tools for automotive repair—a niche that required both durability and a deep understanding of mechanics. Unlike mass-market brands, Lang Tools focused on precision instruments rather than generic hardware. This targeted approach allowed the brand to build loyalty among professional mechanics, many of whom relied on consistent tool performance to maintain productivity. The philosophy from the early days was simple: tools must do more than function; they must endure and feel intuitive in the user’s hands. The company’s early innovations, such as precise brake service tools and specialized thread restorers, reflected a commitment to solving real-world mechanical challenges. Over time, this philosophy cemented Lang Tools’ reputation as not just a toolmaker, but a partner in professional problem-solving.

Product Range and Specialties

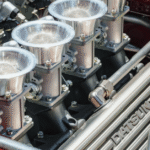

Lang Tools’ product catalog spans a broad yet carefully curated selection of hand tools, each designed with a specific function in mind. Automotive service tools remain at the heart of the lineup, with items like brake caliper wind-back tools, feeler gauges, spark plug thread repair kits, and specialized pullers. These products are often built to withstand both the high torque of mechanical work and the repetitive motion of daily usage. Lang Tools also produces precision measuring instruments, such as micrometers and torque wrenches, which are critical for jobs requiring exact specifications. Beyond automotive tools, the brand has expanded into industrial and maintenance sectors, offering solutions for heavy machinery servicing and custom applications. Their designs often incorporate feedback from industry professionals, ensuring that each tool not only meets, but often exceeds, performance expectations. This focus on functional excellence over flashy marketing is one of the brand’s defining traits, appealing to a clientele that values results over hype.

Table 1: Core Product Categories of Lang Tools

| Product Category | Example Tools | Primary Users | Notable Features |

|---|---|---|---|

| Automotive Service | Brake caliper tools, feeler gauges | Mechanics, repair shops | High durability, precision fit |

| Thread Repair | Spark plug thread kits, rethreading tools | Automotive & industrial mechanics | Heat-resistant materials, accuracy |

| Measuring Instruments | Micrometers, torque wrenches | Engineers, technicians | Calibration accuracy, durability |

| Pullers & Specialty | Bearing pullers, hose removal tools | Maintenance teams | Ergonomic designs, high torque |

| Electrical Service | Wire strippers, crimpers | Electricians, technicians | Clean cuts, secure crimps |

Engineering Philosophy and Quality Control

Lang Tools stands out for its meticulous approach to engineering, combining traditional manufacturing techniques with modern technology. Every tool undergoes rigorous design testing, including stress analysis and real-world simulation, before reaching the market. This process ensures that tools not only meet industry standards but often exceed them in both strength and reliability. Materials are chosen for specific properties—high-carbon steel for durability, chrome finishes for corrosion resistance, and ergonomic polymers for grip comfort. Quality control is not an afterthought but a continuous process, with inspections occurring at multiple production stages. Tools that fail even minor tolerance checks are reworked or discarded entirely. The brand’s commitment to consistency means that a Lang wrench purchased today will match the feel and performance of one bought years ago, giving professionals confidence in replacing or expanding their toolkits without compromising performance. This attention to detail is a key factor in why Lang Tools enjoys long-standing loyalty among its users.

Lang Tools in the Automotive Industry

The automotive repair sector has always been the lifeblood of Lang Tools’ business model. In this field, precision is non-negotiable—small deviations can lead to costly repairs or unsafe vehicles. Lang Tools addresses this demand with products tailored for specific repair tasks, reducing the time and effort needed for intricate jobs. Their brake service kits, for example, streamline the process of compressing calipers, saving mechanics from time-consuming manual adjustments. Similarly, their thread repair tools help salvage damaged components without requiring full part replacements, an approach that saves both time and money. Lang’s close relationship with repair professionals allows them to anticipate market needs; when newer vehicle models introduce unique challenges, Lang Tools often develops corresponding specialty tools quickly. This adaptability ensures that they remain a go-to resource in an industry where technological changes occur rapidly. The brand’s presence in vocational training programs further strengthens its ties to the automotive sector.

Innovation and Material Advancements

Innovation at Lang Tools is not about adding unnecessary features but about enhancing performance through material science and design refinement. The shift towards lighter yet stronger alloys has allowed them to create tools that reduce user fatigue without sacrificing strength. Chrome vanadium steel, for example, is used extensively for its balance of toughness and resistance to wear. Tool handles often feature dual-material grips, combining a firm core for strength with softer outer layers for comfort. Lang Tools also invests in heat-treatment processes that increase tool hardness and extend lifespan, even under constant heavy-duty use. These advancements have made their tools more appealing not just to professionals but also to advanced hobbyists who value industrial-grade quality. Feedback loops with users remain central to this process; a mechanic’s suggestion on grip texture or torque responsiveness can lead to a full redesign in the next production cycle. This iterative improvement model keeps Lang Tools at the cutting edge.

Table 2: Material and Design Innovations at Lang Tools

| Innovation Type | Description | Benefit to Users | Example Application |

|---|---|---|---|

| Chrome Vanadium Steel | Alloy with high strength and durability | Long-lasting performance | Wrenches, sockets |

| Dual-Material Handles | Hard core with soft grip coating | Reduced hand fatigue | Pliers, crimpers |

| Precision Heat Treatment | Controlled heating/cooling of metals | Increased hardness, reduced wear | Screwdrivers, torque tools |

| Corrosion-Resistant Plating | Chrome or nickel finishes | Longer lifespan in harsh environments | Measuring tools, pullers |

| Ergonomic Design Updates | User feedback-based handle and shape changes | Improved usability | Specialty automotive tools |

Global Reach and Distribution

While Lang Tools is rooted in American manufacturing, its reach has expanded globally. Distribution networks now supply their products to tool retailers, automotive workshops, and industrial suppliers across North America, Europe, and parts of Asia. Global expansion comes with the challenge of meeting varying regional standards, but Lang Tools navigates this by adhering to strict international certifications while tailoring packaging and instructions to local markets. This adaptability has made their tools just as relevant in a Tokyo auto shop as in a Detroit garage. The company’s logistics strategy ensures consistent stock availability, reducing downtime for professionals who cannot afford delays. They also work closely with regional distributors to provide after-sales support and warranty services, reinforcing trust in the brand. Despite global expansion, the company maintains its commitment to U.S.-based production for key products, preserving the quality and control that define its reputation.

Training Programs and Industry Support

Lang Tools invests heavily in training initiatives that not only educate users about proper tool usage but also promote industry best practices. These programs often target vocational schools, trade apprenticeships, and professional development courses for seasoned mechanics. By offering hands-on demonstrations and detailed manuals, Lang ensures that its tools are used to their maximum potential. The company understands that even the most well-engineered tools can underperform if users lack the knowledge to handle them effectively. Training sessions often cover safe handling techniques, calibration maintenance for measuring tools, and troubleshooting common workshop challenges. In addition to in-person events, Lang Tools has increasingly embraced digital training modules, allowing technicians to access resources remotely. These educational efforts have a ripple effect across the industry: better-trained professionals mean higher-quality repairs, improved customer trust, and reduced operational errors. In this way, Lang Tools positions itself not just as a supplier, but as a long-term partner in skill development.

Environmental Responsibility and Sustainability

Modern manufacturing faces growing scrutiny over its environmental footprint, and Lang Tools has made notable strides toward sustainability. The company actively works to reduce waste during production, reusing scrap metals wherever possible and optimizing energy consumption in its facilities. Their packaging strategy has shifted toward recyclable materials, reducing the use of single-use plastics and excess cardboard. Beyond the factory floor, Lang Tools advocates for repair over replacement—a principle inherently tied to environmental preservation. By creating tools that extend the life of machinery and components, they indirectly reduce the demand for raw materials and manufacturing energy required for new parts. Furthermore, some of their newest tools feature modular designs, allowing parts to be replaced individually rather than discarding the entire unit. This approach benefits both the environment and the user’s budget. The company also participates in community recycling drives and sustainability-focused trade shows, reinforcing their commitment to being a responsible corporate citizen in the modern era.

Market Position and Competitive Landscape

The hand tool industry is crowded, with brands ranging from budget hardware store lines to premium, niche specialists. Lang Tools occupies a unique position in this spectrum—offering professional-grade quality without entering the ultra-premium pricing tier. Competitors like Snap-on and Matco Tools often dominate high-end mobile distribution channels, while brands such as Craftsman cater more to general consumers. Lang Tools differentiates itself by balancing affordability with professional durability, a combination that appeals strongly to independent mechanics and mid-sized workshops. Their competitive edge lies in specialized tools that solve very specific problems, a niche where generic toolkits often fall short. While some competitors have shifted production overseas to cut costs, Lang’s decision to retain key manufacturing processes domestically gives them tighter control over quality. The brand’s consistency, coupled with steady innovation, has allowed it to hold market share even in times of economic fluctuation, proving that reliability remains a decisive factor for professional buyers.

Customer Feedback and Brand Loyalty

Customer feedback has played a significant role in shaping Lang Tools’ product evolution. Online forums, trade shows, and distributor surveys provide the company with direct insights into user experiences. A recurring theme among satisfied customers is the longevity of Lang Tools products, with many users reporting decades of dependable service from a single tool. Mechanics often highlight the precise tolerances, comfortable grips, and minimal maintenance requirements. However, the company also treats criticism as an opportunity for growth. Instances of handle wear or tool-specific limitations are addressed in subsequent design updates, reflecting a culture of responsiveness. This two-way relationship fosters brand loyalty; when users see their suggestions implemented, they develop a stronger sense of trust and advocacy. Many professionals pass down their Lang Tools to apprentices, turning the brand into a generational presence in workshops. This combination of durability and customer respect reinforces Lang’s position as more than just a supplier—it becomes part of a technician’s career journey.

Technological Integration in Tool Design

As technology reshapes industries, even traditional hand tool manufacturers like Lang Tools are finding ways to integrate new capabilities. For example, some measuring instruments now feature digital readouts that provide more precise data and reduce the margin for human error. Bluetooth-enabled torque wrenches allow for data logging, which can be useful in high-compliance industries like aerospace or specialized automotive work. Lang Tools approaches technology integration cautiously, focusing on features that genuinely improve performance rather than adding novelty. They recognize that overcomplicating tools can reduce reliability in harsh workshop environments. As a result, their technological innovations tend to enhance accuracy, speed, or ergonomic comfort without compromising ruggedness. Collaborations with software developers have also led to digital manuals and maintenance reminders accessible via smartphones, allowing technicians to keep their tools in peak condition. This thoughtful merging of tradition and modern technology ensures that Lang Tools stays relevant in an increasingly digital world.

Global Supply Chain Challenges and Adaptation

The last decade has tested manufacturers with global supply chain disruptions, from raw material shortages to shipping delays. Lang Tools navigated these challenges through a combination of diversified sourcing, domestic manufacturing resilience, and strategic inventory management. They maintain relationships with multiple steel suppliers to avoid dependency on a single source, while also keeping key machining capabilities in-house to reduce reliance on third-party vendors. During the pandemic-related slowdowns, Lang Tools proactively increased its stock of high-demand items, ensuring that workshops relying on their tools experienced minimal downtime. The brand also adopted flexible production scheduling, allowing quick pivots when certain tool categories saw sudden spikes in demand. This adaptability not only helped them weather the crisis but also reinforced their reputation for reliability. By maintaining transparency with distributors and end-users during shortages, they demonstrated an integrity that strengthened customer trust, even in challenging market conditions.

Educational Outreach and Community Engagement

Lang Tools extends its influence beyond the professional sphere by engaging in community and educational outreach. Sponsorship of high school and college-level automotive competitions provides young technicians with access to industry-standard tools, preparing them for careers with proper equipment. The company also participates in community workshops, offering free tool maintenance clinics and safety demonstrations. Such initiatives serve a dual purpose: they enhance the skills of local tradespeople and create brand familiarity early in a professional’s career. Lang Tools has also contributed to vocational program funding, recognizing that strong trade education benefits the entire industry. These outreach programs often include tool donations, which not only help schools save on costs but also ensure that students train with reliable, real-world equipment. By cultivating relationships at the grassroots level, Lang Tools reinforces its role as a brand that values people as much as products, aligning long-term success with community empowerment.

The Future of Lang Tools: Trends and Predictions

Looking ahead, Lang Tools is poised to continue evolving with industry demands while holding onto its core values of durability and precision. One likely area of growth is the integration of more digital features into diagnostic and measuring tools, catering to a new generation of tech-savvy mechanics. Sustainability will also play a larger role, with potential expansions into biodegradable lubricants or fully recyclable tool components. The rise of electric and hybrid vehicles presents opportunities for specialized tool development, as these vehicles require different servicing techniques compared to traditional combustion engines. Furthermore, Lang Tools may expand into modular tool systems that allow customization based on a mechanic’s specific workflow. While embracing innovation, the brand is expected to maintain its focus on quality control and user-centered design—a formula that has served it well for decades. In an industry often swayed by fleeting trends, Lang Tools’ steady hand promises continued relevance and respect.

Expert Opinions and Industry Recognition

Lang Tools has received praise from industry experts for its consistent performance standards and practical innovation. Many trade publications have highlighted its brake service tools as among the best in the market, citing their ease of use and rugged build. Professional associations have awarded the brand for contributions to vocational training and product design excellence. Experts often note that while Lang Tools may not chase the latest flashy marketing campaigns, it invests where it matters—engineering, user feedback, and reliability testing. One veteran mechanic put it succinctly: “A tool you can trust is worth more than one you have to replace every year.” Such endorsements are not just marketing assets but reflections of a brand that has earned its place in workshops through merit rather than hype. This steady stream of recognition cements Lang Tools’ reputation as a professional’s choice in an ever-changing market.

Conclusion

Lang Tools’ story is one of resilience, adaptation, and unwavering commitment to quality. From its origins as a small-scale American manufacturer to its present status as a globally recognized brand, the company has built its legacy on solving practical problems for working professionals. Its dedication to precision engineering, material innovation, and customer collaboration has kept it ahead in a competitive landscape. Whether serving a veteran automotive technician or training the next generation of mechanics, Lang Tools delivers not only equipment but also confidence—confidence that the job will be done right, the first time and every time. As industries evolve with new technologies and environmental expectations, Lang Tools’ blend of tradition and innovation positions it to meet the challenges ahead. In the words of one loyal user, “It’s not just a tool—it’s part of the way you work.” That sentiment encapsulates why, in the hands of professionals, Lang Tools remains a name synonymous with trust.

Frequently Asked Questions (FAQs)

1. What is Lang Tools best known for?

Lang Tools is best known for producing professional-grade automotive service tools, including brake caliper kits, thread repair sets, precision measuring instruments, and specialty pullers. Their products are designed to be durable, accurate, and practical for daily use in workshops.

2. Are Lang Tools made in the USA?

Yes, many of Lang Tools’ core products are manufactured in the United States, allowing the company to maintain strict quality control and consistent production standards.

3. Who typically uses Lang Tools products?

Lang Tools are primarily used by professional mechanics, industrial technicians, vocational schools, and advanced hobbyists who require reliable, precise tools for specialized tasks.

4. How does Lang Tools ensure quality?

The company uses rigorous quality control processes, including multi-stage inspections, precision engineering, and stress testing. Any product that fails to meet specifications is either reworked or discarded.

5. Does Lang Tools offer warranties?

Yes, most Lang Tools products come with a manufacturer’s warranty that covers defects in materials and workmanship, ensuring customers receive dependable service over the product’s lifespan.