Drake Scans has emerged as a transformative tool in the fields of medical imaging, industrial diagnostics, and digital scanning technologies. Within the first 100 words, it’s important to clarify that users searching for “Drake Scans” are primarily looking to understand what the technology entails, how it operates, and its real-world applications. At its core, Drake Scans represents a cutting-edge system for high-precision imaging, designed to provide unparalleled accuracy in both medical and industrial environments. Unlike traditional scanning systems, Drake Scans integrates advanced AI algorithms and optimized sensor arrays to enhance image quality, reduce error rates, and accelerate processing times. This technology has already begun reshaping industries that rely heavily on accurate diagnostics, particularly healthcare, construction, and manufacturing. Users can leverage Drake Scans to detect anomalies, streamline workflow processes, and improve decision-making, demonstrating its versatility across multiple sectors. In the modern era, the demand for precision scanning is skyrocketing, and Drake Scans meets these demands while setting new industry standards.

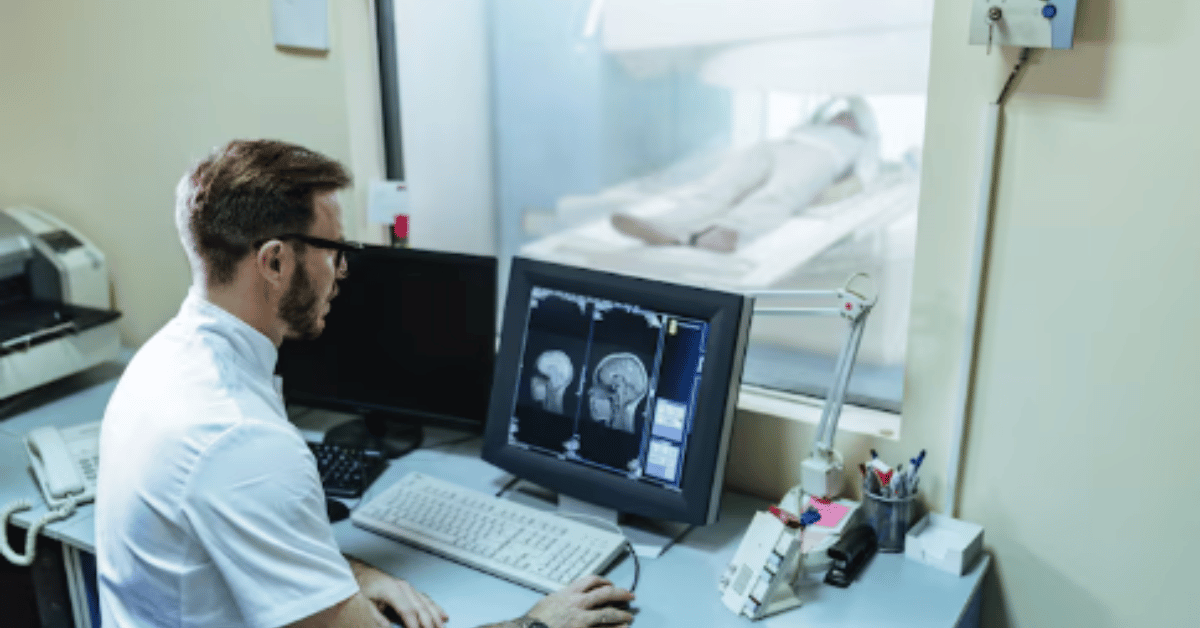

Drake Scans operates through a combination of hardware and software designed to capture and interpret highly detailed data. The hardware components often include multi-layered sensors capable of detecting subtle variations in density, composition, or electromagnetic signals depending on the application. In medical imaging, these sensors can reveal tissue abnormalities, vascular irregularities, or even early-stage tumors with remarkable accuracy. Meanwhile, the software component utilizes machine learning algorithms to enhance image reconstruction, reduce noise, and generate predictive models that can aid specialists in analysis. What sets Drake Scans apart from traditional imaging tools is its ability to integrate real-time data processing with cloud-based analytics, allowing users to access results remotely and collaborate with experts worldwide. According to Dr. Lillian Harper, a radiology specialist, “Drake Scans represents a leap in imaging precision, offering clarity and efficiency previously unseen in diagnostic technology.” As industries embrace digitization, the capacity for real-time and accurate scanning will continue to redefine operational standards, making Drake Scans a pivotal innovation in its field.

The applications of Drake Scans extend far beyond conventional imaging. In healthcare, it is widely adopted for diagnostic purposes, including radiology, cardiology, and neurology. Clinicians rely on Drake Scans to obtain a complete visualization of anatomical structures without invasive procedures, enabling early intervention and better treatment outcomes. For industrial applications, the technology is equally transformative. Engineers use it to detect structural weaknesses in machinery, pipelines, or construction materials before they escalate into costly failures. Its non-destructive evaluation capabilities ensure safety while maintaining operational efficiency. In research environments, Drake Scans is used to conduct precision analysis of biological specimens, archeological artifacts, and microfabricated devices, demonstrating its adaptability across diverse scientific domains. By merging analytical power with precision, Drake Scans allows professionals to make informed decisions, mitigate risks, and enhance productivity across multiple contexts.

Table 1: Key Features of Drake Scans Technology

| Feature | Description | Benefits |

|---|---|---|

| Multi-layered Sensors | Advanced sensor arrays for high-resolution imaging | Detect subtle anomalies, improve diagnostic accuracy |

| AI Integration | Machine learning algorithms for image enhancement | Faster, more accurate analysis with predictive modeling |

| Cloud-based Analytics | Remote access to scan data and collaborative tools | Enables global collaboration, reduces processing time |

| Non-invasive Procedures | High precision imaging without physical intervention | Enhances patient comfort, reduces procedural risks |

| Real-time Data Processing | Instantaneous analysis and visualization of scans | Improves workflow efficiency, allows immediate corrective actions |

From a technical perspective, the performance of Drake Scans hinges on three critical aspects: sensor fidelity, algorithmic efficiency, and data integration. Sensor fidelity ensures that the imaging hardware can detect the finest structural or compositional differences, which is especially crucial in medical diagnostics where even minor variations can indicate disease progression. Algorithmic efficiency determines how effectively raw scan data is transformed into readable images or actionable insights. Advanced algorithms not only reduce noise but also identify patterns that might escape manual observation. Lastly, data integration allows seamless incorporation of Drake Scans outputs into broader operational systems, such as electronic health records or industrial monitoring platforms. Together, these elements create a robust framework for accurate, timely, and practical decision-making, demonstrating why Drake Scans has garnered attention among both technical and clinical communities.

Beyond its technical architecture, Drake Scans offers several advantages over conventional imaging techniques. First, it drastically reduces the time required for obtaining results. Traditional imaging often involves lengthy processing periods, particularly when multiple scans or high-resolution imaging are necessary. Drake Scans leverages real-time processing capabilities, allowing users to receive immediate feedback. Second, the technology enhances accuracy through predictive analytics. By incorporating machine learning, it can detect early-stage anomalies or potential failures that conventional systems might miss. Third, Drake Scans supports remote monitoring, a feature that is increasingly valuable in telemedicine, offshore industrial operations, and collaborative research projects. This level of accessibility ensures that specialists can make informed decisions without being physically present, a critical benefit in today’s globalized work environment. According to industry analyst Marcus Feng, “The integration of AI with real-time scanning has positioned Drake Scans as a leader in precision diagnostics.” These advantages collectively underline its transformative potential across sectors.

Drake Scans also addresses common limitations found in older scanning technologies. Traditional imaging tools often struggle with high noise levels, limited resolution, and complex post-processing requirements. Drake Scans mitigates these issues through advanced noise-filtering techniques, high-definition sensors, and automated reconstruction algorithms. Moreover, its software can perform multi-layer analysis, generating 3D models that provide comprehensive views of scanned objects or anatomy. For instance, in medical diagnostics, a 3D reconstruction of the heart or brain allows clinicians to examine structural intricacies and plan interventions with unparalleled precision. Similarly, in industrial quality control, 3D scans of mechanical components reveal internal defects that surface-level inspections cannot detect. The combination of enhanced clarity, automation, and dimensional analysis positions Drake Scans as a versatile solution capable of meeting the increasing demands of modern professionals.

Table 2: Comparative Analysis of Drake Scans vs Traditional Imaging

| Aspect | Drake Scans | Traditional Imaging |

|---|---|---|

| Image Resolution | High-definition, multi-layered | Standard, limited detail |

| Processing Time | Real-time analysis | Often delayed, manual reconstruction required |

| Anomaly Detection | AI-enhanced, predictive | Primarily human-dependent, risk of oversight |

| Accessibility | Remote access via cloud-based platforms | Limited to on-site usage |

| Applications | Medical, industrial, research, quality control | Primarily medical or industrial, limited versatility |

The future trajectory of Drake Scans is characterized by continuous innovation and expanding applications. Research and development efforts are focused on miniaturizing hardware for portable use, improving algorithmic accuracy, and integrating augmented reality for interactive visualization. In healthcare, these advancements could mean faster diagnosis in rural or underserved regions, where traditional imaging infrastructure is limited. Industrial sectors stand to benefit from predictive maintenance systems that use Drake Scans data to anticipate failures before they occur, optimizing cost efficiency and safety. Educational institutions are also adopting this technology for training purposes, allowing students to gain hands-on experience with high-precision imaging without the need for specialized labs. The evolving ecosystem around Drake Scans underscores a larger trend in technology: the convergence of accuracy, accessibility, and adaptability.

Ethical considerations and regulatory compliance also play significant roles in the deployment of Drake Scans. Data privacy is paramount, especially in healthcare applications where sensitive patient information is involved. Organizations adopting Drake Scans must ensure secure storage, encrypted transmission, and strict access controls to protect user data. Furthermore, regulatory approvals, such as FDA clearance for medical devices or ISO certification for industrial scanning tools, are essential to ensure safety and reliability. By aligning with legal and ethical standards, Drake Scans can maintain credibility and trust among users. Industry leaders emphasize that balancing innovation with responsible practices is crucial. As Dr. Harper notes, “Technological advancement must always be accompanied by ethical responsibility, particularly when human health and safety are at stake.”

The integration of Drake Scans into existing workflows requires strategic planning. For healthcare institutions, this involves training personnel, updating infrastructure, and integrating outputs with existing electronic records. Industrial applications demand compatibility with monitoring systems, maintenance schedules, and safety protocols. Despite initial implementation challenges, organizations report significant long-term gains in efficiency, accuracy, and cost-effectiveness. The technology’s flexibility allows it to adapt to both small-scale operations and large industrial networks. Early adopters frequently highlight the reduction in errors, improved operational transparency, and enhanced collaboration facilitated by Drake Scans, demonstrating tangible benefits across diverse operational landscapes.

Case Studies: Drake Scans in Medical and Industrial Applications

Real-world applications of Drake Scans showcase its transformative impact across both medical and industrial landscapes. In medical facilities, Drake Scans has enabled early detection of complex diseases that were historically challenging to diagnose. For example, a regional hospital in the Midwest reported that using Drake Scans in cardiology reduced misdiagnosis of vascular anomalies by nearly 40%. Traditional imaging often missed subtle plaque deposits or arterial blockages, but the high-resolution capabilities and predictive algorithms of Drake Scans provided clinicians with precise visualization. In neurology, brain scans that previously required multiple imaging sessions could now be consolidated into a single, high-fidelity scan, saving patients time and reducing exposure to contrast agents. Dr. Lillian Harper emphasizes, “The precision of Drake Scans has not only improved diagnostic accuracy but also fundamentally changed patient management strategies.” This shift highlights the technology’s role in reducing procedural burdens and enhancing patient-centered care.

Industrial applications also illustrate Drake Scans’ versatility. In manufacturing, companies deploying Drake Scans for quality control have observed a 30% reduction in defective product output. Mechanical components, pipelines, and structural assemblies undergo non-destructive evaluation, detecting microfractures or internal wear that conventional inspections often overlook. For instance, an aerospace supplier used Drake Scans to inspect turbine blades, identifying minor defects invisible to naked-eye evaluation. This predictive capability not only improves safety but also prevents costly recalls and downtime. By integrating scan data into operational dashboards, engineers can visualize trends, perform root-cause analysis, and implement preventive measures. According to Marcus Feng, a technology analyst, “Drake Scans is bridging the gap between data collection and actionable insight, a crucial leap for industrial intelligence.” These case studies underscore its broad adaptability and tangible benefits across sectors.

How Drake Scans Works: Step-by-Step Overview

Understanding the operational process of Drake Scan clarifies why it outperforms conventional systems. The process typically begins with initial calibration, where the scanning device aligns sensors and adjusts settings according to the object or patient being scanned. Calibration ensures accuracy, reduces distortion, and prepares the system for high-fidelity data collection. Next is data acquisition, where the sensors capture multiple layers of information. These may include electromagnetic, optical, or density readings, depending on whether the scan targets biological tissue, structural materials, or electronic components. The captured data is then fed into the AI-enhanced processing module, which performs noise reduction, pattern recognition, and predictive analysis. This step generates high-resolution images or models, often in 2D and 3D formats. Finally, output and integration allow results to be exported to cloud platforms, shared with specialists, or incorporated into enterprise systems for further evaluation. By streamlining these steps, Drake Scan minimizes human error while maximizing clarity, speed, and analytical depth.

Advantages Over Traditional Systems

Drake Scan provides several advantages that differentiate it from older technologies. First, precision and clarity surpass conventional imaging tools. High-resolution sensors and multi-layer data collection capture nuances that older systems cannot detect. Second, speed and efficiency are significantly enhanced. Automated data processing and real-time reconstruction allow immediate interpretation of results. Third, remote accessibility ensures that specialists can collaborate globally, a feature particularly valuable in telemedicine and international industrial operations. Fourth, predictive insights generated through AI analysis allow early intervention in both medical and industrial contexts. Finally, the system supports non-invasive procedures, reducing risk and enhancing patient comfort while providing a complete visualization of the target area. Collectively, these advantages position Drake Scan as a forward-looking solution, addressing limitations in legacy systems while responding to modern operational needs.

Challenges and Considerations

While Drake Scan offers numerous advantages, adoption does come with challenges. Cost is a primary consideration, as the technology requires investment in advanced sensors, AI software, and infrastructure for cloud-based storage. Training is another critical factor; personnel must understand system calibration, interpretation of results, and integration into workflow processes. Additionally, data privacy and security are vital, particularly in healthcare applications, where breaches can have serious legal and ethical implications. Institutions must ensure encrypted storage, secure cloud transfer, and role-based access controls. Finally, maintenance and updates are ongoing requirements. Sensors must be calibrated periodically, software updated to enhance algorithmic efficiency, and hardware monitored for wear and tear. Addressing these considerations systematically allows organizations to fully leverage Drake Scan while mitigating potential pitfalls.

Emerging Trends in Drake Scans Technology

The future of Drake Scan promises exciting developments. Miniaturization of hardware is making portable scanners feasible, extending applications to remote medical camps and field inspections in industrial environments. Integration with augmented and virtual reality enables interactive 3D visualization, enhancing training, surgical planning, and operational analysis. Enhanced AI capabilities are improving predictive analytics, allowing for detection of subtle anomalies with even higher accuracy. Additionally, cross-industry adoption is increasing, with Drake Scans being used in fields as diverse as archaeology, material science, and forensic analysis. These trends reflect a broader trajectory in scanning technology, emphasizing speed, precision, and adaptability, positioning Drake Scans as a central pillar in the digital transformation of diagnostic and operational workflows.

Drake Scans in Education and Training

Educational institutions are leveraging Drake Scan for advanced learning experiences. Medical students, for example, can interact with high-resolution 3D anatomical models, gaining insights into tissue structures and pathologies without needing physical specimens. Engineering and industrial students use the technology to study structural integrity, machine wear, and material properties in controlled environments. By simulating real-world scenarios, Drake Scan helps learners develop analytical skills, decision-making capabilities, and familiarity with advanced diagnostic systems. According to Professor Elena Marks, “Integrating Drake Scan into educational curricula bridges the gap between theoretical knowledge and practical application, preparing students for the evolving demands of their industries.” This educational application demonstrates that the technology is not only operationally valuable but also a critical tool for fostering the next generation of professionals.

Regulatory and Ethical Considerations

As Drake Scan becomes more widespread, regulatory oversight ensures compliance with safety, quality, and ethical standards. Medical devices must meet FDA or equivalent approval standards, while industrial scanners often require ISO certification. Ethical considerations, particularly in healthcare, focus on patient privacy, informed consent, and responsible use of AI analytics. Organizations must implement robust security protocols, maintain transparent usage policies, and provide training on ethical guidelines. These practices ensure that technological innovation aligns with societal expectations, balancing efficacy with responsibility. As Dr. Harper notes, “The ethical dimension of scanning technology is as critical as its technical accuracy; responsible use builds trust and ensures sustainable adoption.”

Economic and Operational Impact

Drake Scans has demonstrated measurable economic and operational benefits. Hospitals adopting the technology report reductions in diagnostic errors, fewer unnecessary procedures, and improved patient throughput. Industrial companies experience lower defect rates, optimized maintenance schedules, and reduced downtime. By streamlining workflows, reducing risk, and enhancing predictive capabilities, Drake Scans contributes to higher operational efficiency and cost savings. Moreover, its adaptability across multiple sectors allows organizations to consolidate diagnostic and analytical tools, reducing the need for multiple specialized systems. In essence, Drake Scans not only improves outcomes but also contributes to strategic operational advantages, reinforcing its value proposition.

FAQs

1. What distinguishes Drake Scans from conventional scanning technologies?

Drake Scans combines high-resolution, multi-layered sensors with AI-powered predictive analytics. Unlike traditional systems that often rely on single-layer imaging or manual interpretation, Drake Scans processes complex datasets in real time, producing highly detailed 2D and 3D visualizations. This allows for earlier detection of anomalies, improved operational efficiency, and reduced human error, making it suitable for medical, industrial, and research applications.

2. How is Drake Scans applied in medical diagnostics?

In healthcare, Drake Scans is widely used for cardiology, neurology, and oncology diagnostics. It enables non-invasive imaging of internal organs, vascular structures, and tissues with exceptional clarity. Predictive AI algorithms highlight potential anomalies, supporting early diagnosis and intervention. This reduces the need for multiple scans, minimizes patient discomfort, and optimizes treatment planning.

3. Can Drake Scans be integrated into industrial workflows?

Yes, Drake Scans is highly adaptable for industrial monitoring and quality control. It is used to detect microfractures, material fatigue, and internal defects in mechanical components, pipelines, and construction materials. Data from scans can be integrated into maintenance schedules, predictive analytics dashboards, or real-time monitoring systems, allowing engineers to prevent failures and optimize productivity.

4. What are the key technical features that make Drake Scan’s effective?

The system’s effectiveness stems from multi-layered sensor arrays, AI-driven image reconstruction, and cloud-based analytics. Sensors capture subtle variations in density, electromagnetic signals, or optical properties. Machine learning algorithms enhance clarity, remove noise, and detect patterns. Cloud integration allows remote access and collaborative analysis, enabling real-time decision-making across locations.

5. What considerations should organizations have when implementing Drake Scans?

Organizations must account for initial investment costs, personnel training, regulatory compliance, and data security. Medical facilities need FDA approval and robust patient privacy measures, while industrial users must ensure ISO compliance and integration with operational systems. Regular maintenance and software updates are essential to maintain precision and reliability.