In both industrial design and health sciences, the term “expander” encapsulates a diverse range of devices engineered to perform a simple yet transformative task—create controlled expansion. Whether you’re diving into orthodontic treatment plans or exploring pipeline maintenance systems, chances are you’ll encounter some variation of the expander. For those searching to understand what an expander is and how it fits into various applications, the answer lies in its core purpose: to apply force in a targeted way that increases space, pressure, or volume without breaking the existing system. From expanding palates to expanding metal tubes, the utility of expanders has grown across industries and continues to evolve.

This article takes a deep dive into the multi-functional world of expanders, covering dental, mechanical, industrial, and even consumer applications. It explores how expanders are constructed, the principles behind their mechanics, and the different contexts in which they are utilized. You’ll also learn how recent innovations are enhancing the efficiency and adaptability of expanders in multiple fields. Our purpose is to equip readers with a complete, up-to-date understanding of what expanders are, why they matter, and where they are heading in the future. “In every application, an expander isn’t just a tool—it’s a gateway to transformation,” notes Dr. Rhea Lin, a biomedical engineer at NY Tech Labs. As you read further, you’ll discover that the versatility of expanders is limited only by the imagination of those designing them.

What is an Expander?

At its essence, an expander is a mechanical or structural tool designed to increase space or volume. These devices work by exerting pressure on their environment in a specific and controlled manner, leading to expansion. While this sounds straightforward, the variety in design and function of expanders is vast. Dental expanders, for example, are commonly used to widen the upper jaw in children and adolescents to correct bite issues or create space for tooth alignment. Meanwhile, in mechanical engineering, pipe expanders are used to resize pipe diameters, especially in situations where welding or cutting would be inefficient or unsafe.

In all cases, the central concept remains the same: to apply a directed force outward from a central axis to cause expansion. This is usually done incrementally and precisely. Expanders are typically made from durable materials like stainless steel, aluminum, or high-grade polymers to withstand the forces they need to apply. The type of material often correlates with the specific purpose—for instance, bio-compatible plastic in dental applications versus titanium in aerospace settings. Because they come in so many forms, understanding an expander begins with identifying its intended function.

Classification of Expanders: Key Types and Their Functions

Expanders are not one-size-fits-all; they are designed according to the specific requirements of the field they serve. In general, expanders can be grouped into five broad categories: dental, mechanical, industrial, cosmetic, and orthopedic. Each category offers distinct mechanisms and goals, as shown in the table below.

| Type of Expander | Primary Function | Common Materials | Use Case Example |

|---|---|---|---|

| Dental Expander | Widening jaw structure | Plastic, Stainless Steel | Orthodontic palate expansion |

| Pipe Expander | Increasing pipe diameter | Steel, Titanium | Pipeline fitting in construction |

| Tissue Expander | Stretching skin or muscle | Silicone, Rubber | Reconstructive surgeries |

| HVAC Tube Expander | Enlarging tubing in AC systems | Steel, Aluminum | Heat exchanger manufacturing |

| Orthopedic Expander | Bone lengthening or alignment | Titanium, Polymer | Limb deformity correction |

Each of these expanders has a unique method of deployment, whether it involves manual screws, hydraulic systems, or programmable pressure regulators. Their design has become increasingly specialized, with recent technological advancements allowing for greater precision and reduced side effects in medical applications, and enhanced strength and efficiency in industrial ones.

The Evolution of Dental Expanders: A Medical Milestone

Dental expanders have dramatically improved over the years, becoming a cornerstone of early orthodontic intervention. Most commonly used in children aged 6 to 14, these devices gradually widen the upper jaw by exerting lateral force. This creates more space in the mouth for teeth to align properly and can eliminate the need for tooth extractions later. “What used to take years of cumbersome appliances can now be done in months, thanks to modern expanders,” says Dr. Elise Montero, an orthodontist based in Manhattan.

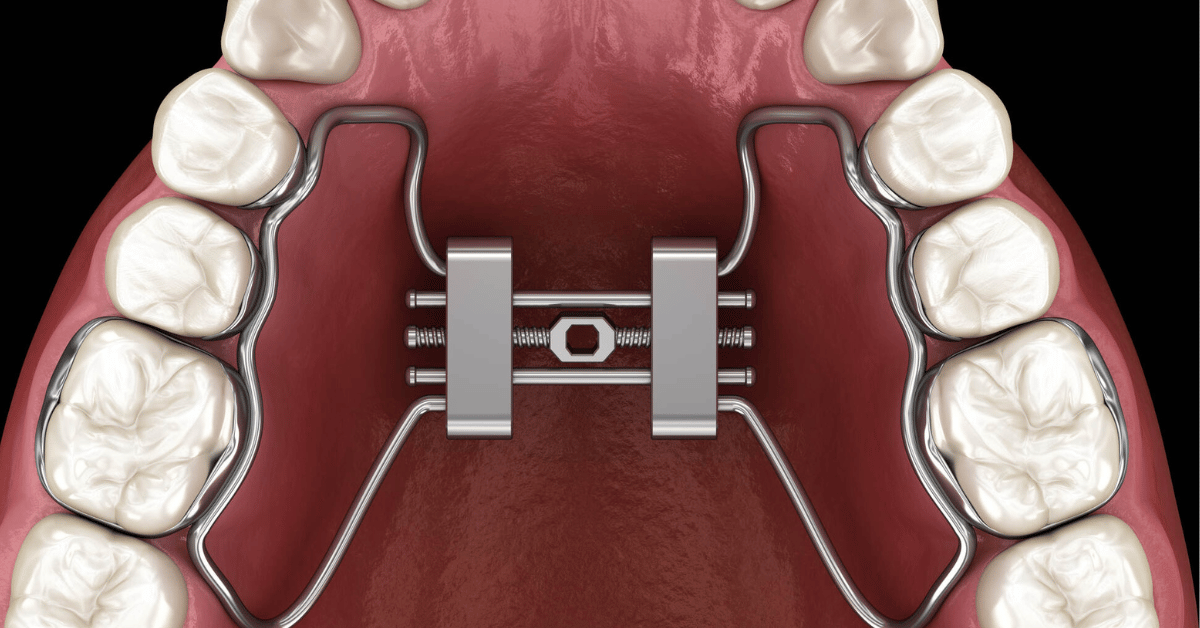

The most common type is the Rapid Palatal Expander (RPE), a fixed device attached to the upper molars with a central screw mechanism. This screw is turned incrementally, typically by parents at home, to gradually widen the mid-palatal suture. Other variants include the Quad Helix and Hyrax expanders, each with its own set of indications based on patient age, bone density, and treatment goals.

The integration of 3D scanning and digital modeling has made custom expander fabrication more accurate. With 3D-printed expanders, orthodontists can now tailor the fit and pressure points with extreme precision, minimizing discomfort and maximizing results.

Industrial Expanders: Tools of Modern Engineering

Industrial expanders serve a vital role in sectors like construction, oil & gas, HVAC, and heavy manufacturing. One of the most prominent examples is the pipe expander. These tools are inserted into pipes and activated—either hydraulically or manually—to increase the internal diameter. This is crucial for joining pipes of different sizes, repairing dents, or enhancing fluid flow capacity.

The designs vary based on application. For instance, segmental expanders use interlocking petals that unfold under pressure to create uniform expansion. Cone-shaped expanders offer tapered widening and are especially useful in conical connections. In aerospace, expanders are even used in fuselage assembly to stretch metallic tubing with precision tolerance.

Here’s an overview of industrial expander subtypes:

| Subtype | Working Mechanism | Application Area | Notable Advantage |

|---|---|---|---|

| Hydraulic Expander | Uses hydraulic pressure | Pipelines, HVAC | High force, low manual effort |

| Manual Tube Expander | Screw or handle-based | Plumbing, AC units | Cost-effective and portable |

| Segmental Expander | Expands in segments | Oil refineries, Power plants | Uniform expansion |

| Cone Expander | Tapered design | Automotive assembly | Smooth, gradient resizing |

| Pneumatic Expander | Air-powered expansion | Light metal fabrication | Speed and efficiency |

Innovations in material science have allowed these devices to handle higher stress environments while reducing wear and tear, which is crucial for long-term operational safety and cost management.

Tissue Expanders in Cosmetic and Reconstructive Surgery

Perhaps the most life-changing use of expanders lies in medicine—specifically, reconstructive and cosmetic surgeries. Tissue expanders are inflatable silicone devices placed beneath the skin to stretch it over time. This stretched skin can later be used for reconstructive purposes, such as covering areas affected by burns, trauma, or surgical removal of tissue.

Once implanted, the expander is gradually filled with a saline solution over several weeks. This slow expansion encourages the skin to grow naturally, providing a source of healthy, well-matched tissue for subsequent procedures. Surgeons appreciate the predictability and safety of modern expanders. “Tissue expansion is a biological marvel—it’s the body responding and adapting to engineered stimuli,” says Dr. Malcolm Osei, a plastic surgeon in Boston.

Recent developments include remote-controlled expanders, which use magnetic or wireless systems to manage saline inflow without frequent clinical visits. This not only improves the patient experience but also allows for real-time adjustment based on tissue response.

Technological Advancements: Smart Expanders and 3D Engineering

As technology progresses, expanders are becoming smarter. Digital sensors, remote actuation, and self-adjusting mechanisms are being incorporated into next-gen expanders. These intelligent systems provide clinicians or engineers with real-time feedback, allowing for dynamic control based on current conditions.

One notable example is the Smart Palatal Expander, which features embedded sensors that monitor force application and jaw response. Another is the auto-regulating hydraulic expander used in aerospace projects, which adjusts its force output based on detected resistance and heat profiles. These intelligent devices not only improve results but also minimize human error and reduce the margin for mechanical failure.

Moreover, the rise of 3D printing has transformed expander prototyping and customization. Engineers and medical practitioners can now fabricate expanders tailored to individual structural or anatomical specifications, reducing fitting errors and increasing functionality. These developments signify a future where expanders are not just passive tools but responsive systems.

Economic and Market Trends in Expander Manufacturing

The global market for expanders has seen consistent growth, particularly in the medical and industrial sectors. As of 2025, the expander industry is valued in the multi-billion-dollar range, with projections showing continued expansion driven by innovation and increasing demand.

The growth is primarily due to three factors:

- Rising demand in orthodontics and reconstructive surgeries.

- Infrastructure growth requiring pipeline and tube modifications.

- Emergence of 3D-printed and smart expanders.

North America remains the dominant market due to high healthcare spending and technological access, followed by Europe and Asia-Pacific. Industrial applications, especially in HVAC and energy infrastructure, are leading contributors to revenue streams.

As environmental and energy regulations become stricter, expanders are also being designed to meet sustainability benchmarks—using recyclable materials, minimizing energy use, and enhancing lifespan.

The Future of Expanders: Trends and Emerging Applications

Looking forward, expanders are poised to become more adaptive, efficient, and minimally invasive. In medicine, we can expect to see bioresorbable expanders that gradually dissolve once their job is done. In engineering, lightweight composites and nanotechnology will create expanders with unmatched strength-to-weight ratios.

Additionally, fields like robotics and space exploration are starting to use miniature expanders for maneuvering limbs or instruments in constrained environments. Even consumer technologies—such as ergonomic wearables or portable fitness devices—are exploring expander systems for adjustability.

In the words of materials scientist Dr. Kaelyn Rivers: “The expander is no longer just a mechanical device—it’s an adaptable framework for progress.”

Conclusion

From simple mechanical tools to advanced smart systems, expanders occupy a foundational yet transformative role across industries. Whether widening a child’s jaw, adjusting a pipe fitting, or stretching tissue for reconstructive surgery, the principles of expansion are applied with precision, purpose, and innovation. The evolution of expanders—from manual screws to sensor-integrated systems—demonstrates how this once-basic concept has evolved into a high-tech, cross-disciplinary marvel.

As global demand grows and technology continues to advance, expanders will become even more integrated into the design of future systems, be it in healthcare, construction, energy, or consumer tech. In every application, the expander is more than just a device—it’s a symbol of calculated growth and engineered transformation. As we move into an increasingly adaptive and responsive world, expanders remind us that sometimes, the path forward begins with making space.

FAQs

Q1. What is an expander used for?

An expander is used to create space or increase dimensions in dental, industrial, surgical, or mechanical systems.

Q2. Are expanders painful to use in orthodontics?

Mild discomfort is common, but modern expanders are designed to minimize pain with gradual, controlled expansion techniques.

Q3. How long does a tissue expander stay in the body?

Tissue expanders typically remain in place for 6 to 12 weeks, depending on the desired skin growth and surgical plan.

Q4. Can expanders be customized for individual patients or systems?

Yes, 3D printing and digital modeling now allow highly personalized expander designs in both medical and industrial contexts.

Q5. Are there smart expanders available today?

Yes, smart expanders with sensors and remote controls are now used in medical and engineering fields for real-time adjustments.