Orange spline paste has emerged as a term that often sparks curiosity among readers searching for clarity about its meaning, applications, and significance. Simply put, orange spline paste refers to a specialized material blend designed for alignment, bonding, and fine adjustment processes in engineering, manufacturing, and even creative industries. In the first 100 words, the essential idea is clear: this material functions as a versatile compound, engineered to assist in creating smooth, precise connections between surfaces or mechanical elements where flexibility and resilience are necessary. For many, the term might appear technical or even abstract, but beneath its niche identity lies a concept that bridges industrial utility with innovation.

Understanding orange spline paste requires moving beyond a definition into the actual world of practice: how it works, why it is manufactured with specific properties, and how professionals employ it for real outcomes. Whether used in small-scale precision mechanics, large construction settings, or even in conceptual artistic mediums, the compound carries multiple values. It resists wear, enhances grip, minimizes stress fractures, and optimizes surface interactions where typical adhesives or fillers may fail. What makes it particularly fascinating is the color-coded formulation—orange—distinguishing it within industry circles as a product meant for visibility, safety awareness, and classification. This introduction builds the foundation for exploring orange spline paste from its composition to its evolving future, presenting not just what it is, but also why it matters.

What is Orange Spline Paste?

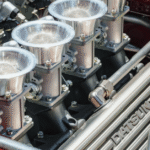

Orange spline paste can be defined as a highly engineered viscous compound created to support joints, surfaces, or spline mechanisms by adding elasticity, reinforcement, and stability. The term “spline” refers to ridges or grooves typically found in machinery, tools, or systems where interlocking elements must fit seamlessly. Traditional splines demand careful alignment, and a paste formulation provides a solution for micro-adjustments, thermal expansion gaps, or lubrication-like buffering. Unlike simple adhesives, orange spline paste is formulated to retain flexibility while maintaining its bonding strength.

Manufacturers developed orange spline paste not as a universal adhesive, but as a targeted aid for industries demanding controlled cohesion. Engineers use it to reduce vibration, artists may apply it for structured texture, and technicians rely on it for splines that need consistent load distribution. Its bright orange tint is more than aesthetic—it offers immediate visibility during applications, making it easier to monitor coverage, detect uneven spots, and ensure safety checks. In practice, orange spline paste combines utility with thoughtful design, serving multiple roles while solving specific mechanical challenges.

Composition and Properties of Orange Spline Paste

The success of orange spline paste lies in its carefully balanced composition. Unlike ordinary fillers, its formulation includes elastomers, micro-polymers, and stabilizers designed for both strength and adaptability. Its texture is neither too rigid nor too fluid, giving users the capacity to mold and apply it across uneven splines or delicate areas. Another key property is thermal stability. Unlike compounds that crack or degrade under temperature fluctuations, orange spline paste can withstand both hot and cold environments without losing cohesion.

Its chemical properties also resist common corrosive agents such as oils, greases, or mild acids, making it highly durable for industrial purposes. This resilience allows orange spline paste to last longer in machinery compared to conventional lubricants or temporary fillers. Engineers often note that its elasticity is its defining feature: it expands and contracts slightly under stress, ensuring that splines remain tightly aligned while minimizing the risk of surface fractures. Furthermore, its orange pigmentation acts as a built-in marker, ensuring consistent identification throughout manufacturing lines. In terms of measurable performance, orange spline paste offers a balance between strength, visibility, and longevity unmatched by typical alternatives.

Applications of Orange Spline Paste

Orange spline paste finds practical application in diverse sectors due to its adaptability and resilience. In mechanical engineering, it is applied within rotating shafts, gears, or coupling mechanisms where splines endure repetitive stress. Its paste-like texture ensures uniform distribution, reducing wear and prolonging operational lifespan. Construction industries utilize it to align fixtures, especially where vibration or shifting loads could loosen conventional fasteners. For aerospace and automotive industries, the paste offers thermal and structural reliability, making it an ideal choice for systems subjected to fluctuating pressures and extreme conditions.

Outside heavy industries, orange spline paste also finds creative uses. In architecture and design, it may be employed for prototype modeling or textured finishes that require both form and resilience. Artists working with mixed media sometimes adapt similar compounds for durable sculptural elements. This surprising versatility highlights that the paste is not confined solely to machines but extends into human creativity as well. In every context, orange spline paste provides one unifying benefit: it bridges gaps—both literal and metaphorical—between rigid systems and the need for flexible cohesion.

Table 1: Key Properties of Orange Spline Paste

| Property | Description |

|---|---|

| Color | Bright orange for visibility and classification |

| Texture | Viscous, moldable, allows precise application on splines and uneven areas |

| Elasticity | Expands and contracts under stress without cracking |

| Thermal Stability | Withstands both high and low temperature fluctuations |

| Resistance | Strong against oils, greases, and mild corrosive elements |

| Industrial Use | Enhances spline alignment, reduces wear, supports vibration resistance |

Advantages of Using Orange Spline Paste

The advantages of orange splines paste extend beyond its immediate bonding capabilities. Its foremost benefit is the ability to improve machinery reliability by reducing frictional stress at contact points. While traditional lubricants may dissipate over time, orange splines paste remains semi-solid, offering long-term coverage. Its elasticity provides an added safeguard against sudden mechanical shocks, distributing impact forces evenly to reduce potential failures.

Another advantage lies in visibility. In industries where safety is paramount, technicians need assurance that materials are correctly applied. The bright orange hue eliminates guesswork, enabling quick checks and minimizing human error. This visibility also makes training easier for newcomers learning to handle complex spline systems. Environmental advantages include reduced waste: because the paste remains effective longer than alternatives, fewer replacements are needed, lowering material consumption. For professionals balancing efficiency, safety, and sustainability, orange splines paste offers an impressive triad of advantages.

Limitations and Considerations

Despite its strengths, orange spline paste’s not a universal solution. One limitation is cost, as its specialized formulation makes it more expensive than generic adhesives or fillers. Its application also requires training; improper handling can lead to over-application, which may interfere with spline motion. Another consideration is compatibility. While the paste performs well with metals, certain plastics or sensitive coatings may react differently, requiring pre-testing before use.

Additionally, long-term exposure to extremely corrosive chemicals could still degrade its properties, meaning industries operating in highly aggressive environments must evaluate alternatives or additional protective layers. From an aesthetic standpoint, while orange is useful for visibility, it may not be desirable in applications demanding a clean or neutral appearance. These limitations do not diminish the compound’s overall value, but they emphasize the importance of thoughtful usage based on context.

Table 2: Comparison of Orange Spline Paste with Alternatives

| Material/Compound | Strengths | Weaknesses |

|---|---|---|

| Orange Spline Paste | Elastic, visible, thermally stable, long-lasting | Higher cost, limited plastic compatibility |

| Generic Adhesives | Low cost, widely available | Brittle under stress, poor thermal stability |

| Industrial Lubricants | Reduce friction, inexpensive | Short-lived, low visibility, lacks structural aid |

| Epoxy Fillers | Strong bonding, rigid | Cracks under stress, limited elasticity |

Future Prospects of Orange Spline Paste

The future of orange spline paste’s tied to evolving industrial and creative needs. As industries move toward automation and precision manufacturing, materials that can self-adjust, resist wear, and ensure alignment will gain prominence. Research into smart materials suggests that orange spline paste may evolve into sensor-embedded compounds capable of signaling wear levels or stress. Innovations in eco-friendly formulations could make it more sustainable, reducing reliance on petrochemical bases.

In creative fields, its texture and resilience may attract designers looking for durable yet malleable mediums. Its potential to cross boundaries between industries highlights a growing recognition of hybrid materials that serve multiple disciplines. As one engineer once remarked, “The best materials are those that refuse to stay in one box—they adapt.” This perspective suggests that orange splines paste will not remain confined to its original niche but will continue to expand into unexpected areas of human ingenuity.

Conclusion

Orange splines paste represents more than just a technical compound; it stands as an example of innovation that balances flexibility, durability, and visibility. From aligning delicate machinery to reinforcing creative projects, its applications stretch far beyond its initial engineering context. Its advantages—thermal stability, elasticity, and resistance—make it indispensable in many fields, while its limitations remind professionals to apply it wisely. Perhaps most importantly, orange splines paste embodies the shift toward specialized materials designed with both utility and human factors in mind.

In the words of a manufacturing expert, “A small compound can change the way an entire system holds together.” This is particularly true for orange splines paste, which has proven itself as a subtle yet transformative force. As industries and creative sectors evolve, its relevance is likely to grow, reflecting an enduring demand for materials that not only solve immediate problems but also anticipate the future of precision, safety, and sustainability.

FAQs

Q1. What is orange spline paste primarily used for?

Orange spline paste’s primarily used for aligning, cushioning, and reinforcing spline connections in mechanical, industrial, and structural systems. Its elasticity makes it suitable for reducing stress and wear while maintaining precision.

Q2. Why is orange spline paste colored orange?

The bright orange color is intentional. It enhances visibility during application, helps monitor coverage, and ensures safety compliance in industrial environments.

Q3. How does orange spline paste differ from regular adhesives?

Unlike adhesives that harden rigidly, orange splines paste remains elastic, offering both bonding and shock absorption for splines and joints.

Q4. Is orange spline paste resistant to extreme temperatures?

Yes, orange spline paste’s designed to withstand both high and low temperature fluctuations, maintaining its structural integrity under stress.

Q5. Can orange splines paste be used on all materials?

It works effectively with metals and many composites, but compatibility with certain plastics and sensitive coatings should be tested before full application.