Silikon, often mistaken for silicon due to their similar names, stands as one of the most transformative synthetic materials shaping the 21st century. Unlike silicon, which is a natural chemical element used primarily in semiconductors, silikon is a flexible, rubber-like polymer known for its resilience, temperature resistance, and diverse industrial applications. From healthcare to automotive design, consumer electronics to construction, silikon’s adaptability has made it a cornerstone of material science innovation. This article explores every dimension of silikon — from its chemical structure to its global market role, sustainability prospects, and emerging technologies that rely on its versatile nature.

Within the first hundred words, it’s essential to understand what silikon truly is: a synthetic polymer made primarily of silicon, oxygen, carbon, and hydrogen. It is used in sealants, lubricants, medical implants, and kitchenware, celebrated for its non-reactivity, stability, and resistance to extreme environments. What makes silikon particularly fascinating is its ability to bridge the gap between rigid materials like plastics and soft materials like rubber, allowing it to serve countless roles in manufacturing and innovation. “Silikon is not just a material; it’s a silent enabler of progress,” as one materials scientist aptly put it.

The Chemical Composition and Structure of Silikon

At its core, silikon is composed of repeating units of siloxane (Si-O-Si), combined with organic side groups attached to the silicon atoms. This molecular arrangement gives silikon its distinctive flexibility and durability. The Si-O bond is significantly stronger than a typical carbon-carbon bond, granting silikon remarkable thermal and chemical stability. Its resistance to oxidation and ultraviolet radiation allows it to maintain performance in harsh conditions, from deep-sea environments to aerospace applications.

The unique combination of inorganic and organic properties makes silikon a hybrid material. This hybrid nature means it doesn’t fit neatly into traditional categories of natural or synthetic polymers. Its inorganic backbone gives it strength and resilience, while the organic groups provide versatility and softness. As a result, silikon can be formulated into liquids, gels, foams, or solid rubbers depending on industrial requirements. The ability to customize its structure has driven the material’s exponential adoption across multiple sectors.

Historical Development and Evolution

The history of silikon traces back to the early 20th century, when scientists began experimenting with silicon-based polymers to create heat-resistant rubbers. It was in the 1940s, during wartime research, that silicone rubber first became commercially viable. Companies such as Dow Corning and General Electric played pivotal roles in developing early silikon compounds for electrical insulation and mechanical seals. Over time, the material transitioned from specialized military use to mass consumer applications.

By the 1960s and 1970s, silikon had found its place in medical devices and household products, symbolizing a new era of materials engineering. It evolved beyond being a laboratory curiosity into a material of convenience and safety. As industries pursued lighter, more efficient, and environmentally stable materials, silikon met the challenge with consistent performance. The progression from early experimental forms to today’s medical-grade, food-safe, and aerospace-approved silikons represents a century-long journey of scientific refinement and industrial adaptation.

Applications of Silikon in Modern Industries

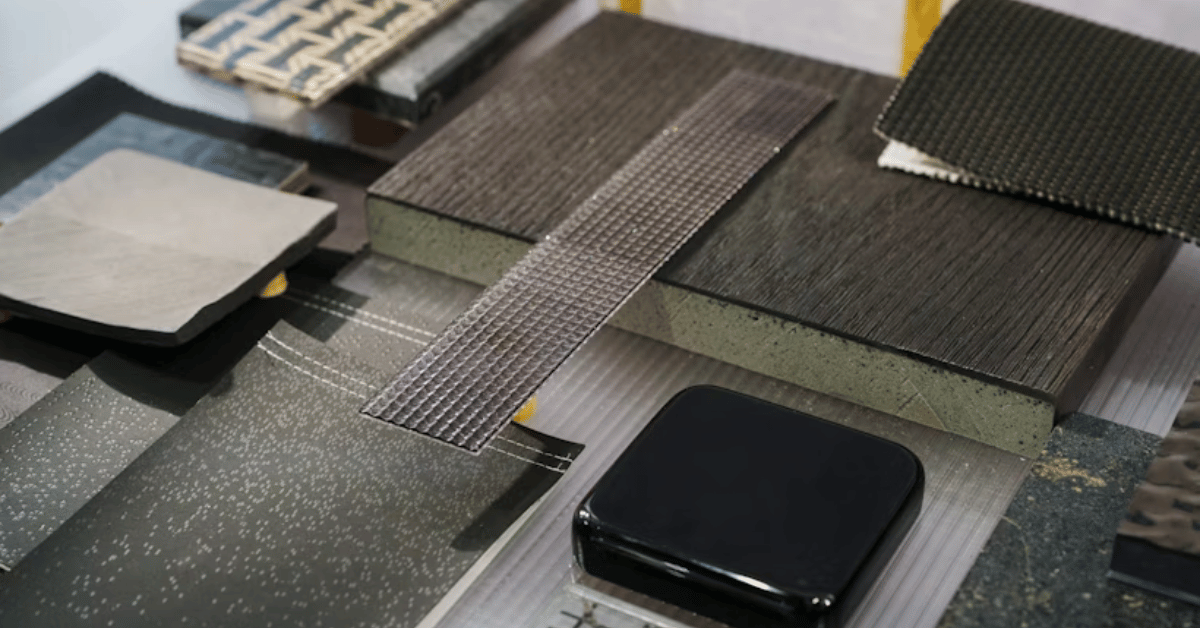

Silikon’s applications today are vast and deeply embedded in modern life. In healthcare, it’s used in prosthetics, catheters, and medical tubing due to its hypoallergenic and biocompatible nature. In the automotive industry, silikon seals and gaskets provide resilience against extreme temperatures and mechanical stress. Electronics rely on silikon-based adhesives and insulators to protect delicate circuits from heat and moisture. Even in cosmetics, silikon enhances the texture and durability of products like lotions and hair conditioners.

The food industry values silikon for its non-stick, heat-resistant properties, making it a popular material in baking molds and kitchen utensils. In construction, silikon sealants play a vital role in waterproofing and glazing high-rise structures. Its widespread utility stems from one defining trait — adaptability. Silikon performs consistently under conditions that degrade traditional materials, ensuring reliability and longevity. As one industry analyst notes, “Every sector that values endurance and stability eventually finds its way to silikon.”

Table 1: Major Applications of Silikon Across Industries

| Industry | Common Uses | Key Benefits |

|---|---|---|

| Healthcare | Implants, catheters, prosthetics | Biocompatible, non-toxic, flexible |

| Automotive | Seals, gaskets, hoses | Heat resistant, durable, non-corrosive |

| Electronics | Insulators, adhesives | Thermal stability, moisture protection |

| Construction | Sealants, coatings | Weatherproofing, elasticity |

| Consumer Goods | Cookware, cosmetics | Safe, reusable, aesthetic versatility |

The Science of Thermal and Chemical Stability

One of silikon’s defining features is its exceptional resistance to heat and chemicals. It can endure temperatures ranging from -60°C to 230°C without degrading, making it indispensable for environments with fluctuating conditions. This resilience is rooted in the Si-O-Si bond, one of the strongest chemical linkages found in polymer chemistry. The same structure that resists heat also resists chemical attack, which is why silikon remains inert even when exposed to oils, solvents, or acids.

This characteristic explains why silikon is widely used in laboratory and industrial settings where exposure to reactive substances is common. It retains flexibility even after years of use, unlike many organic polymers that harden or crack. “Silikon’s resistance to time and temperature makes it a scientific marvel,” remarks a materials engineer. The ability to combine softness with endurance has made silikon an irreplaceable asset in precision manufacturing and scientific research.

Innovations in Silikon Technology

Over recent decades, silikon technology has undergone significant evolution. Advanced formulations such as liquid silikon rubber (LSR) and high-consistency rubber (HCR) have expanded its usability in automated manufacturing. LSR, in particular, is revolutionizing product design due to its injection molding capabilities, allowing for precise, complex geometries with minimal waste. Innovations in surface modification have also made silikon more adhesive or more slippery, depending on functional needs.

Emerging nanocomposite technologies are enhancing silikon’s electrical and mechanical properties. By embedding nanoparticles, researchers are creating silikon materials with improved conductivity, flexibility, or antimicrobial performance. Furthermore, sustainability-driven research has led to partially bio-based silikon formulations that reduce dependence on petroleum-derived components. These innovations demonstrate silikon’s enduring relevance and adaptability in an age increasingly focused on efficiency and environmental responsibility.

Table 2: Types of Silikon and Their Characteristics

| Type | Physical Form | Common Use | Distinct Feature |

|---|---|---|---|

| RTV (Room Temperature Vulcanizing) | Flexible sealant | Construction, repairs | Cures at room temperature |

| HCR (High Consistency Rubber) | Solid rubber | Automotive, electronics | Strong mechanical properties |

| LSR (Liquid Silikon Rubber) | Liquid form | Medical, molding | Precise molding, biocompatibility |

| Gels | Semi-solid | Medical cushioning | Soft, flexible, transparent |

| Fluorosilicone | Modified polymer | Aerospace, fuel systems | Chemical and fuel resistance |

Environmental and Health Considerations

While silikon is prized for durability, its environmental impact is an evolving discussion. It does not biodegrade easily but is less harmful than plastics because it doesn’t release toxic byproducts when disposed of properly. Recycling silikon remains challenging but achievable through mechanical grinding and reformation into secondary products. Some manufacturers are investing in closed-loop silikon recycling systems to minimize waste.

In health contexts, silikon’s inert nature ensures safety in medical and food applications. It doesn’t leach harmful substances, nor does it react with biological tissues, making it suitable for long-term implants. However, environmentalists advocate for improved disposal infrastructure to manage silicone waste responsibly. The goal is to ensure sustainability while maintaining the benefits of a material that continues to define industrial reliability.

Market Growth and Global Demand

The global silikons market has experienced consistent growth over the past two decades, driven by technological advancement and expanding industrial applications. Emerging economies have become significant contributors to this growth, particularly in Asia, where consumer manufacturing and healthcare sectors rely heavily on silicone-based materials. The trend is shifting toward specialized, high-performance silikons that can withstand unique operational demands, from renewable energy systems to electric vehicle production.

Market analysts predict further expansion as sustainability pressures lead to the development of eco-friendly formulations and recycling processes. The medical silikons market, in particular, shows accelerated growth due to aging populations and the increasing demand for advanced prosthetic materials. As technological innovation continues to redefine manufacturing priorities, silikons remains at the center of that evolution, bridging material science and modern necessity.

Future Outlook: Sustainable Silikon and Smart Integration

The future of silikons lies in combining material innovation with digital technology. Research into “smart silikon” integrates sensors and electronic capabilities directly into flexible silikons substrates. These intelligent materials could revolutionize wearable healthcare devices, enabling seamless monitoring and comfort. Sustainability is also becoming a guiding force, with new formulations aiming to reduce environmental footprints.

“Tomorrow’s silikons will think, adapt, and heal,” predicts a leading materials futurist. The transition from inert to interactive silikons opens possibilities in robotics, medical diagnostics, and even soft prosthetics that mimic natural skin movement. As industries embrace circular economy models, silikon’s recyclability and longevity make it a sustainable choice for the long run.

Cultural and Economic Impact

Beyond technical uses, silikon holds a subtle but meaningful cultural presence. Its integration into beauty, fashion, and household products symbolizes modern efficiency and cleanliness. Economically, the silikons industry supports a broad network of manufacturing, research, and retail sectors worldwide. The value chain stretches from raw material suppliers to end-product designers, creating global employment and innovation ecosystems.

Silikons represents the intersection of science and lifestyle — where chemistry meets comfort. Its ability to influence sectors as diverse as architecture, medicine, and art speaks to its universal adaptability. Just as steel defined the industrial revolution, silikons defines the era of soft, intelligent materials.

Ethical Production and Industrial Responsibility

With great demand comes responsibility. Ethical silikons production now emphasizes reducing energy consumption, eliminating hazardous byproducts, and ensuring safe working environments in manufacturing plants. Global regulatory frameworks are being developed to oversee material quality, particularly for medical-grade silikons. Transparency in sourcing and formulation is key to maintaining consumer trust and corporate accountability.

Manufacturers that adopt cleaner production methods not only meet compliance but also gain competitive advantage. As consumers grow more environmentally conscious, brands that highlight sustainable silikons use often enjoy enhanced reputation and loyalty. The industry’s ethical evolution mirrors the global shift toward more responsible material science.

Conclusion

Silikons has evolved from a laboratory discovery into a global material phenomenon — one that quietly supports modern civilization. Its unique balance of flexibility, resilience, and stability has made it indispensable in healthcare, construction, electronics, and beyond. As industries shift toward smarter and greener technologies, silikon’s story continues to expand, blending chemistry with innovation and environmental consciousness. “The beauty of silikon,” as one researcher remarked, “is that it never stops adapting.”

From the smallest medical device to the largest architectural seal, silikons defines the invisible infrastructure of progress. Its journey reflects humanity’s ongoing quest to create materials that endure, enhance, and inspire. With every new formulation, silikons reaffirms its role not just as a tool of convenience but as a symbol of intelligent material design — flexible, durable, and future-ready.

FAQs

1. What is the difference between silikon and silicon?

Silikon is a synthetic polymer made from silicon, oxygen, carbon, and hydrogen, known for its flexibility and heat resistance. Silicon, on the other hand, is a natural chemical element used mainly in semiconductors and electronics.

2. Is silikon safe for medical and food use?

Yes. Medical-grade and food-grade silikons are rigorously tested to ensure biocompatibility and non-toxicity. They are widely approved for implants, cooking tools, and food storage products.

3. Can silikon be recycled?

While recycling silikon is complex due to its chemical stability, new mechanical and thermal recovery processes are emerging. Many companies are now investing in silicone recycling initiatives to minimize waste.

4. How is silikon contributing to sustainability?

Silikon contributes to sustainability by offering long-lasting performance and reducing the need for frequent replacements. Ongoing research aims to develop bio-based silikon and efficient recycling systems to lower environmental impact.

5. What are the future innovations in silikon technology?

Future innovations include smart silikon with integrated sensors, bio-based silikon materials, and recyclable composites designed for medical, automotive, and electronic applications.